■ NZ-75 TROLLEY CONVEYOR

■ USE As shown in the table below, NZ-Trolley Conveyor is using for heavy and light-weight paint lines and assembly lines with a maximum weight of 50kg or less. It is the most common type to be used.

■ NZ-75 Chain Specification We produce 3 types of NZ-75, depending on the type and weight, quantity, speed, length, temperature and operation ways will be considered and used. If you have any further questions, please feel free to contact our sales department at any time (010-4886-2752 Mr.Yoo byung chul) or click the mail as below.

∙ E-mail : sewoong02@sewoong.com

|

Dimension |

Chain pitch |

Chain tension

allowance |

Breaking load |

Chain weight |

Max allowable load per

Hanger |

|

NZ-75 Chain |

75mm |

500kg |

5,300kg |

P-type: 4.2kg/M

B-type: 5kg/M |

Single: 25kg

U: 50kg |

|

Min. Hanger pitch |

Standard radius of

curvature of rail |

Max speed |

|

150mm |

R600 over |

15m/min |

Products with 40 Links x 75 = 3,000mm will be packed in a box

NZ-75 Chain has

three types such as Press type, Turned type and Bearing type. You

may choose what

you need.

∙ Categorized NZ-75 CHAIN as type and application

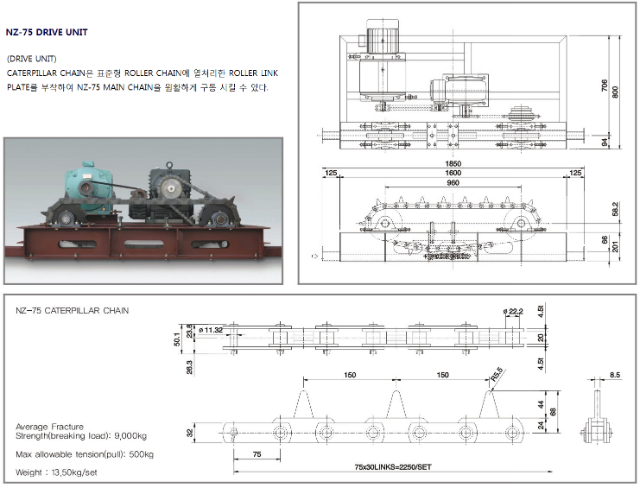

∙ NZ-75 DRIVE UNIT, TAKE-UP UNIT

DRIVE UNIT

We applied the sprocket Drive to be easy maintenece. Calculating the chain tension with

LAY-OUT should be done to select specification of the Motor and Reducer.

We are specialized in manufacturing the Drive with Caterpillar.

∙ It

is recommended to install at the highest location on the rail

∙ It

is advantageous to locate the driving unit right before downwarded slope for

the

purpose of back tension.

∙ Not

to install at an insecure location for the loads, where the tension of chain is

unable

∙ To

concentrate curve rails in the rear of the driving unit in order to reduce the

final

tension of the chain. To place it in the rear of unloading point, and not

in the front

side of the loading point

∙ It

causes knocking if there are more than places with minus(-)tension for one

drive

which should be avoided

∙ (note) Long horizontal section in the front side of downward curve has minus(-)

tension

TAKE-UP UNIT

The ways of TAKE-UP

have Weight type, Spring type and Screw type. Weight type

is available for

drying line, line where high temperature is required and long line,

Spring type

and Screw type are available for simple line.

∙ To be installed in the location of

minimum tension of the rail chain,and in the rail chain,

and in the rear of

driving unit. It is not good to place it in the rear upward slope

∙ Even though it is right before

driving unit, installation before downward slope is

unfavorable. Installation

after downward slope is recommended

∙ HANGER PARTS

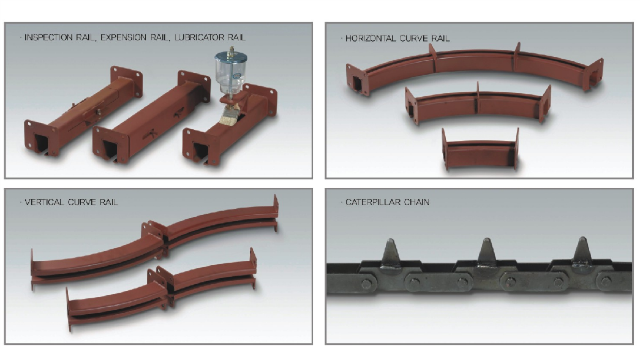

∙ NZ-75 RAIL PARTS

|